Ứng dụng sản phẩm

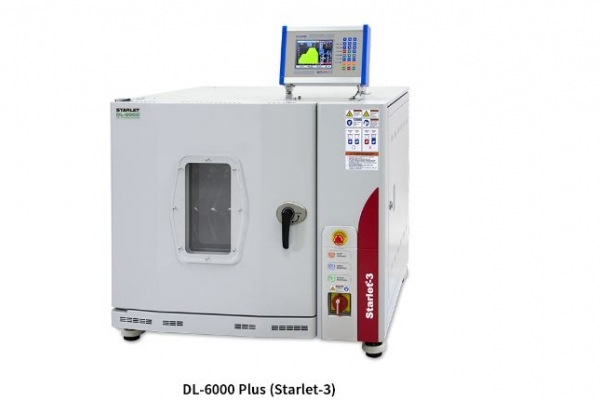

- The fabric will be dried evenly on both sides which will give the fabric minimal shrinkage and stretch.

- By means of the continuous stenter, the upper and lower two nozzles air circulation system balance the temperature distribution, same air velocity, gas volume. which results in equal drying.

- Precise temperature control by PID auto-tuning function.

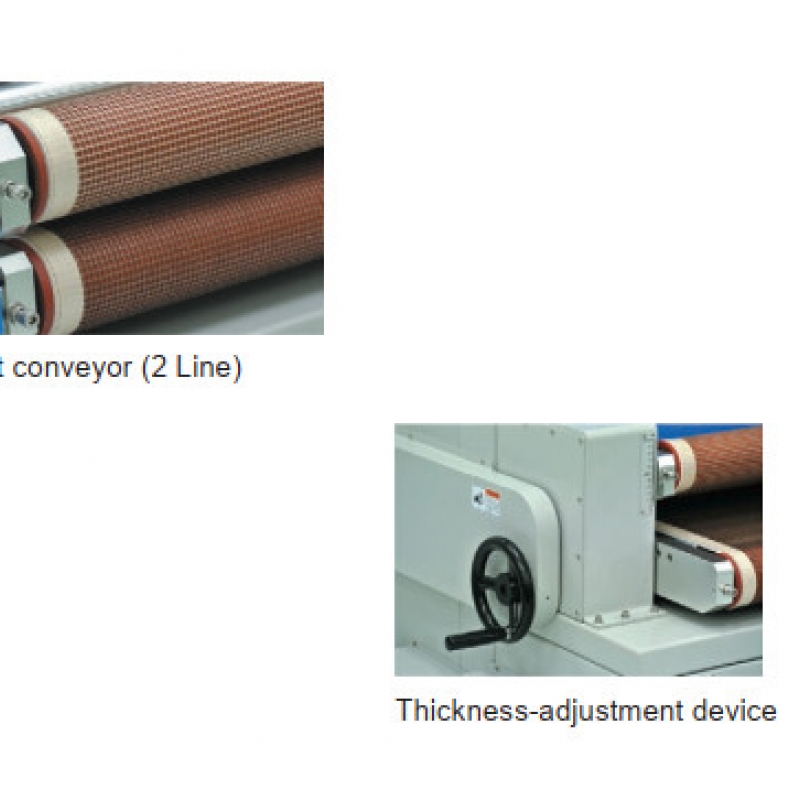

- The continuous slit nozzle feels soft and can also be used for Nonwovens, Pile Fabrics, Brushed Fabrics.

- Due to the thickness adjustment (5mm~100mm) of the mesh conveyor belt, the lattice state yarn can form non-woven at high temperature.

- Multi-stage exhaust fan on the roof keeps the right amount humidity inside the chamber to prevent yellowing of light colored fabrics.

- For the 2-chamber system, it is possible to set different temperatures in the first & second chamber.

- Just the end of the exit is equipped with an up & down cooling system.

- Same airflow with production mesh dryer results in good repeatability

Thông số kỹ thuật

| Bề rộng làm việc |

100~600mm |

| Chiều dài làm việc |

Max. 1.55m |

| Tốc độ sấy |

0.2~5m/min. |

| Bề dày mẫu |

Có thể điều chỉnh ( max 100mm) |

| Điều khiển nhiệt |

Digital PID type |

| Khoảng nhiệt |

20~250℃ |

| Công suất gia nhiệt |

60kW (Step adjuster-4 step) |

| Vòi phun |

2ea (Up & Down) |

| Lưu lượng vòi |

0~5m/sec. |

| Hướng phun |

Có thể điều chỉnh |

| Động cơ |

0.75kW 3 phase |

| Công suất quạt |

6.0kW 3 phase (1.5kW x 4ea) |

| Công suất quạt làm mát |

120W 3 phase (60W x 2ea) |

| Nguồn điện |

380VAC 50/60Hz 3 phase |

| Trọng lượng |

1200kg (±5Kg) |

| Kích thước |

2500(W) x 1100(D) x 1720(H)mm |

Tiêu chuẩn

Video

Please contact us for advice and support

⇒ Mr. Ba: 0948.27.99.88

⇒ Or leave a message and we will call you directly. Thank you very much!

![Process Mini Dryer [Mini Tenter / Automatic Discharge Dryer / Coating Curing Machine]](/temp/-uploaded-nhuom_hoantat_6_cr_600x400.jpg)